roof and floor coating with 2K PUR top coat

** brilliant colours and high UV resistance **

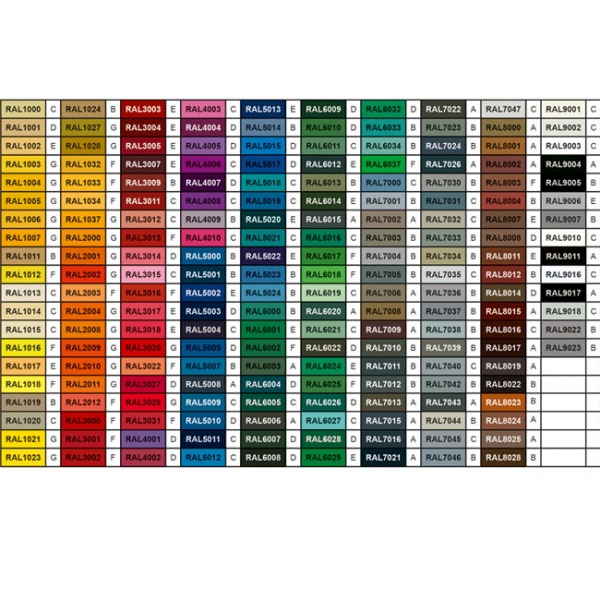

High-quality 2-component epoxy resin systems in combination with modern glass fabric reinforcement and a 2K PUR top coat for the highest demands and long-lasting UV protection.This system is more durable and robust than any conventional films. The 2K PUR top coat is available in almost all RAL colours on request!

The perfect basis for waterproofing, wrinkle-free coatings or extensive green roofs!

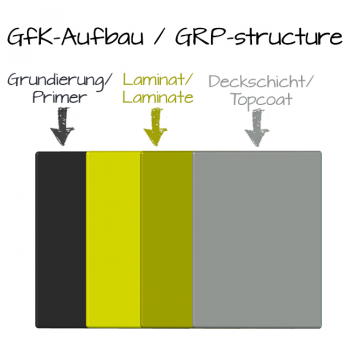

From the primer to the laminating and top coat, this complete GRP set contains all products you need for the individual roof coating!

Further advantages of our glass reinforced plastic (GRP) coating, in addition to its high resistance to animal claws, stones and impact loads, are the following aspects:

✔ simple "do it yourself" system solution

... choice of different colours

... offers for special or larger projects available on request!

✔ excellent substrate for green roofs

... can also be installed without expensive profiles

✔ high water and chemical resistance

... effective protection against moisture damage

The application only requires a little manual skill and the observance of a few basics in handling the materials. All relevant information and tips can be found in our detailed instructions and in our practical videos!

Hint:

We recommend using our tool sets that have already been composed - they contain the right tools for every roof size!

For white shades, 3 - 4 coats are required. The additionally required quantity must be ordered separately!

procedure for a GRP coating

Attention: For white shades, 3 - 4 coats are required. The additionally required quantity must be ordered separately!

video instruction for a GRP coating

Premium PLUS sets: roof coating with 2K PUR top coat

* For white shades, double the amount of HP-PP is needed, as more coats are required.

1x HP-XB | thinner - 250 ml

10.50 m² HP-B450/635E | glass fabric - width: 63 cm

5x HP-E30TLS | epoxy resin laminating system - 1.4 kg

1x HP-PP | 2K PUR top coat – 0.75 ltr. *

1x HP-XB | thinner - 250 ml

21.00 m² HP-B450/635E| glass fabric - width: 63 cm

10x HP-E30TLS | epoxy resin laminating system - 1.4 kg

1x HP-PP | 2K PUR top coat – 1.5 ltr. *

1x HP-E80FS | epoxy resin primer system - 1.6 kg

1x HP-XB | thinner - 1000 ml

31.50 m² HP-B450/635E| glass fabric - width: 63 cm

7x HP-E30TLS | epoxy resin laminating system - 3 kg

1x HP-PP | 2K PUR top coat – 0.75 ltr. *

1x HP-PP | 2K PUR top coat – 1.5 ltr. *

1x HP-XB | thinner - 1000 ml

42.00 m² HP-B450/635E | glass fabric - width: 63 cm

10x HP-E30TLS | epoxy resin laminating system - 3 kg

1x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-XB | thinner - 1000 ml

52.50 m² HP-B450/635E | glass fabric - width: 63 cm

13x HP-E30TLS | epoxy resin laminating system - 3 kg

1x HP-PP | 2K PUR top coat – 0.75 ltr. *

1x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-E80FS | epoxy resin primer system - 4 kg

1x HP-XB | thinner - 1000 ml

63.00 m² HP-B450/635E | glass fabric - width: 63 cm

15x HP-E30TLS | epoxy resin laminating system - 3 kg

1x HP-PP | 2K PUR top coat – 1.5 ltr. *

1x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-E80FS | epoxy resin primer system - 4 kg

1x HP-XB | thinner - 1000 ml

73.50 m² HP-B450/635E | glass fabric - width: 63 cm

18x HP-E30TLS | epoxy resin laminating system - 3 kg

1x HP-PP | 2K PUR top coat – 0.75 ltr. *

1x HP-PP | 2K PUR top coat – 1.5 ltr. *

1x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-E80FS | epoxy resin primer system - 1.6 kg

1x HP-E80FS | epoxy resin primer system - 4 kg

1x HP-XB | thinner - 1000 ml

84.00 m² HP-B450/635E | glass fabric - width: 63 cm

20x HP-E30TLS | epoxy resin laminating system - 3 kg

2x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-E80FS | epoxy resin primer system - 4 kg

1x HP-XB | thinner - 1000 ml

94.50 m² HP-B450/635E | glass fabric - width: 63 cm

23x HP-E30TLS | epoxy resin laminating system - 3 kg

1x HP-PP | 2K PUR top coat – 0.75 ltr. *

2x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-XB | thinner - 1000 ml

105.00 m² HP-B450/635E | glass fabric - width: 63 cm

25x HP-E30TLS | epoxy resin laminating system - 3 kg

1x HP-PP | 2K PUR top coat – 1.5 ltr. *

2x HP-PP | 2K PUR top coat – 3 ltr. *

2x HP-E80FS | epoxy resin primer system - 4 kg

1x HP-XB | thinner - 1000 ml

126.00 m² HP-B450/635E | glass fabric - width: 63 cm

30x HP-E30TLS | epoxy resin laminating system - 3 kg

3x HP-PP | 2K PUR top coat – 3 ltr. *

2x HP-XB | thinner - 1000 ml

147.00 m² HP-B450/635E | glass fabric - width: 63 cm

35x HP-E30TLS | epoxy resin laminating system - 3 kg

1x HP-PP | 2K PUR top coat – 1.5 ltr. *

3x HP-PP | 2K PUR top coat – 3 ltr. *

2x HP-XB | thinner - 1000 ml

168.00 m² HP-B450/635E | glass fabric - width: 63 cm

40x HP-E30TLS | epoxy resin laminating system - 3 kg

4x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-E80FS | epoxy resin primer system - 12.8 kg

2x HP-XB | thinner - 1000 ml

283.50 m² HP-B320/635E | glass fabric - width: 63 cm

45x HP-E30TLS | epoxy resin laminating system - 3 kg

1x HP-PP | 2K PUR top coat – 1.5 ltr. *

4x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-E80FS | epoxy resin primer system - 12.8 kg

2x HP-XB | thinner - 1000 ml

315.00 m² HP-B320/635E | glass fabric - width: 63 cm

50x HP-E30TLS | epoxy resin laminating system - 3 kg

5x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-E80FS | epoxy resin primer system - 4 kg

1x HP-E80FS | epoxy resin primer system - 12.8 kg

2x HP-XB | thinner - 1000 ml

330.75 m² HP-B320/635E | glass fabric - width: 63 cm

55x HP-E30TLS | epoxy resin laminating system - 3 kg

1x HP-PP | 2K PUR top coat – 1.5 ltr. *

5x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-E80FS | epoxy resin primer system - 1.6 kg

1x HP-E80FS | epoxy resin primer system - 4 kg

1x HP-E80FS | epoxy resin primer system - 12.8 kg

2x HP-XB | thinner - 1000 ml

362.25 m² HP-B320/635E | glass fabric - width: 63 cm

60x HP-E30TLS | epoxy resin laminating system - 3 kg

6x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-E80FS | epoxy resin primer system - 12.8 kg

1x HP-XB | thinner - 5000 ml

393.75 m² HP-B320/635E | glass fabric - width: 63 cm

65x HP-E30TLS | epoxy resin laminating system - 3 kg

1x HP-PP | 2K PUR top coat – 1.5 ltr. *

6x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-XB | thinner - 5000 ml

425.25 m² HP-B320/635E | glass fabric - width: 63 cm

70x HP-E30TLS | epoxy resin laminating system - 3 kg

7x HP-PP | 2K PUR top coat – 3 ltr. *

1x HP-XB | thinner - 5000 ml

456.75 m² HP-B320/635E | glass fabric - width: 63 cm

75x HP-E30TLS | epoxy resin laminating system - 3 kg

1x HP-PP | 2K PUR top coat – 1.5 ltr. *

7x HP-PP | 2K PUR top coat – 3 ltr. *

technical data sheets and working instructions

| epoxy resin primer system HP-E80FS | [PDF] |

| epoxy resin laminating system HP-E30TLS | [PDF] |

| 2K PUR top coat HP-PUR-PLUS | [PDF] |

| thinner HP-XB | [PDF] |

| glass fabric HP-B320/635E | [PDF] |

| step-by-step instructions | [PDF] |

| processing epoxy resins | [PDF] |

| processing HP-PUR-PLUS | [PDF] |

"Tips for building"!

Hazard statements

Resin component:

Warning

H315 Causes skin irritation.

H317 May cause an allergic skin reaction.

H319 Causes serious eye irritation.

H411 Toxic to aquatic life with long lasting effects.

Hardener component:

Danger

H314 Causes severe skin burns and eye damage.

H317 May cause an allergic skin reaction.

H411 Toxic to aquatic life with long lasting effects.

Resin component:

Warning

H315 Causes skin irritation.

H317 May cause an allergic skin reaction.

H319 Causes serious eye irritation.

H411 Toxic to aquatic life with long lasting effects.

Hardener component:

Danger

H302+H332 Harmful if swallowed or if inhaled.

H314 Causes severe skin burns and eye damage.

H317 May cause an allergic skin reaction.

H412 Harmful to aquatic life with long lasting effects.

Resin component:

Danger

H226 Flammable liquid and vapour.

H312 Harmful in contact with skin.

H315 Causes skin irritation.

H332 Harmful by inhalation.

H335 May cause respiratory irritation.

H336 May cause drowsiness and dizziness.

H411 Toxic to aquatic life with long lasting effects.

H412 Harmful to aquatic life with long lasting effects.

Hardener component:

Warning

H226 Flammable liquid and vapour.

H304 May be fatal if swallowed and enters airways.

H315 Causes skin irritation.

H317 May cause allergic skin reaction.

H319 Causes severe eye irritation.

H331 Toxic by inhalation.

H332 Harmful by inhalation.

H334 May cause allergy, asthma-like symptoms or breathing difficulties if inhaled.

H335 May cause respiratory irritation.

H336 May cause drowsiness and dizziness.

H411 Toxic to aquatic life with long lasting effects.

Danger

Highly flammable liquid and vapour.

May be fatal if swallowed and enters airways.

Causes skin irritation. Repeated exposure may cause skin dryness or cracking

Causes serious eye irritation.

Harmful if inhaled.

May cause respiratory irritation.

May cause drowsiness or dizziness.

May cause damage to organs through prolonged or repeated exposure.

frequently asked questions

- more durable than any conventional liner and resistant to animal claws, stones and impact loads.

- wrinkle-free pool design and easy incorporation of connections such as skimmers, drains, nozzles, etc.

- problem-free "do it yourself" system solution. No welded seams and can be extended or redesigned at any time. Also coloured...

Shipping information

✔ shipping by parcel service

... up to a total weight of approx. 50 kg

... delivery time is one to two days

✔ shipping by forwarding agent (on pallet)

... from a total weight of approx. 50 kg

... delivery time is two to four days

... arrangement of a delivery date by telephone

✔ express delivery

... for particularly urgent deliveries

... please contact us for more information

✔ shipment tracking

... you will receive the link immediately after the goods have been dispatched.

✔ control on receipt of goods

... please check the order for condition and completeness

... have the goods been damaged during shipment? Then refuse to accept the goods or have the delivery person acknowledge the external damage.

... are there any other problems? Feel free to contact us at any time

05905 / 9454110

05905 / 9454110 Kontakt

Kontakt